23 Nov 2015 Spotlight on Analytic Systems

In this week’s Spotlight on Tech, we are hearing from Jim Hargrove, President of local advanced manufacturing company Analytic Systems, to learn all about the company – from where they got their start to how they grew their revenue to over $10 million by 2014.

My name is Jim Hargrove. I took over Analytic Systems from my father in 1993. It’s hard to believe that I have been guiding the company for 23 years already. The previous ten years from 1983 to 1993 were spent in the process of building and selling a line of products as co-founder, VP and chief engineer of ComNav Marine, so when I assumed leadership of Analytic Systems we decided to duplicate the process, but with the focus on power conversion.

In 1994 there was my father, myself and one employee and I wondered what I had gotten myself into. But we persevered and little by little the company grew until around 2000 we finally broke the million dollar barrier. One of the products we were working on was a military power supply for the US Army and when we won the contract to build these power supplies in 2002, it doubled the size of the company overnight and Analytic Systems has leveraged that work to grow to over $10 million in revenue by 2014.

These types of power supplies typically use machined parts, either the enclosures or mounting blocks or a variety of other pieces. One of the biggest bottlenecks in our process was the machining, so we made the decision in 2005 to do our own machining and bought one CNC Vertical Mill that year. Several years later, when that one machine was running two shifts a day, 6 days a week, we decided we needed to expand and, by chance, a company called Metal Action Machining was for sale. We bought the company in 2009 and moved it to our location in Surrey, just as we were relocating Analytic Systems from that Surrey location to Tilbury Industrial Park in Delta.

We have continued to invest in Metal Action and it now has Vertical Machining, Horizontal Machining, 5 Axis and Mill Turn capabilities. Metal Action is ISO9001 and AS9100 certified and specializes in products and services for the Electronics Industry in aluminum, copper, brass, bronze and stainless steel including extruded chassis or heatsink cutting and machining, billet mounting blocks, billet heat sinks, billet Fan Housings, planar transformer mounting brackets, planar transformer windings, transformer winding jigs, billet enclosures, conductive standoffs, bus bar cutting and machining, die cast box machining and much more.

Design services are available in MasterCam, Solidworks and PTC Creo including 3D modelling. Finishing services including anodizing, powder coating, laser etching, laser engraving, and machine engraving. As a trusted partner to Analytic Systems, Metal Action knows the requirements of the electronics industry from the inside out and its services are available to all high tech companies in the Northwest.

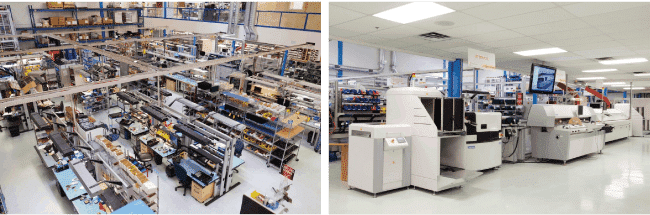

We have also invested heavily in our manufacturing capabilities at Analytic Systems, as we believe very strongly in ‘Made in North America’, and, particularly, ‘Made in BC’. Surface Mount Assembly using the latest automation, wave soldering, CNC conformal coating and full design and assembly services in leaded and lead free processes are now being offered to the electronics community of Western Canada and Northwestern USA.

I am very proud of what we have built right here in the Lower Mainland, and would love to show our capabilities to any of our member companies of the BCTIA who may be interested. For a tour or a quotation, please contact me directly at jim@analyticsystems.com or jim@metalactionmachining.com.

Jim Hargrove, P.Eng.

To learn more about Analytic Systems, visit them online at www.analyticsystems.com

If you’d like us to shine the spotlight on your company, email hello@wearebctech.com today!